Tom qab lub tswv yim thiab cov khoom ntawm cov yas yas tau coj mus rau hauv kev lag luam hauv tsev, lawv tau txais kev pom zoo los ntawm qee lub tuam txhab thiab cov neeg siv khoom, thiab tom qab ntawd cov khoom yas ntoo tau tshwm sim hauv cov khoom siv hauv tsev.Cov ntaub ntawv tseem ceeb hauv tsev ntoo yog muab faib ua PE ntoo yas thiab PVC ntoo yas.

PE ntoo yas khoom muaj cov dej tsis zoo thiab tiv thaiv corrosion, siab hardness, thiab raug thermal deformation thiab buckling, tab sis cov thickened los yog ntxeem tau hollow qauv muaj cov nyhuv zoo.

1. Cov khoom lag luam muaj lub neej ntev rau kev siv sab nraum zoov;Nws yog tam sim no siv rau 3-5 xyoo;

2. Cov oxidation kuj thiab lub teeb decomposition kuj tsis zoo.Txawm hais tias tus neeg sawv cev tiv thaiv cov pa oxygen thiab UV siv tus neeg saib xyuas ntxiv, cov nyhuv tsis zoo, thiab cov khoom siv zog thiab xim ceev yuav cuam tshuam;

3. Cov tsos ntawm cov khoom yog ntshiab xim, tsis muaj woodiness, thiab cov tsos mob tsis zoo.

1. PVC ntoo yas khoom tuaj yeem ua los ntawm cov ntaub ntawv tshiab lossis cov khoom qub (thaum cov khoom PE ua los ntawm cov ntaub ntawv tshiab yog kim dhau los nkag rau hauv kev lag luam).Nws kuj yog qhov yooj yim rau kev hloov kho, thiab cov nyiaj ntxiv nyob ntawm qhov ntau lawm thiab zoo;

2. PVC tuaj yeem ua rau cov khoom siv yas uas tsis tshua muaj foaming, yog li tus nqi qis dua.Co extrusion (ob npaug ntawm cov khoom siv ntau yam co extrusion lossis steel yas co extrusion) tuaj yeem siv tau yog tias tsim nyog, thiab lub zog thiab ntoo lis xav tau zoo;

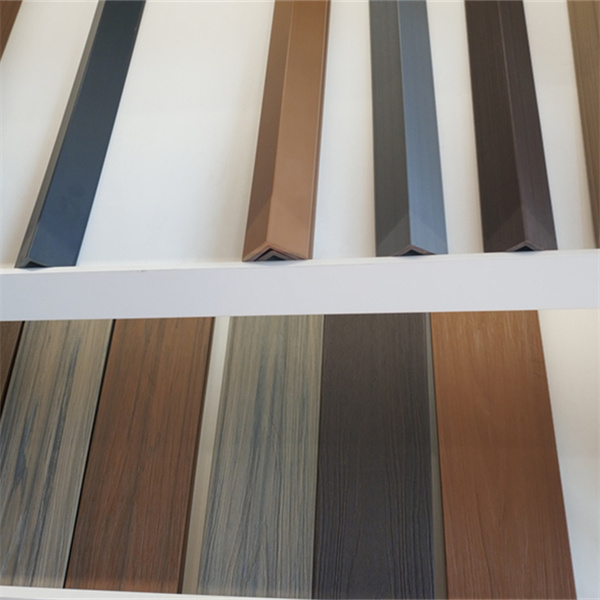

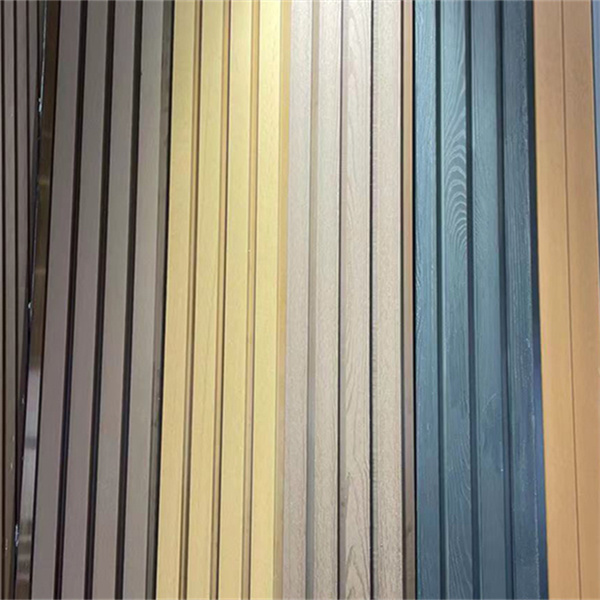

3. PVC tuaj yeem siv rau kev ua haujlwm thib ob ntawm ntau cov qauv saum npoo los yog xim npog UV xim, thiab cov khoom zoo saib thiab muaj xim zoo nkauj;

4. Cov dej tsis zoo thiab tiv thaiv corrosion ntawm PVC ntoo yas khoom kuj zoo heev.

① Cov txheej txheem kev npaj sib txawv: PE cov khoom yas yas yog npaj los ntawm txoj kev thawb txias;Kev npaj ntawm PVC ntoo yas khoom yuav muab faib ua lub tshuab nqus tsev molding, txias extrusion thiab peb yob suppression.

② Cov ntaub ntawv sib txawv: PE ntoo yas yog tsim los ntawm cov khoom siv thib ob thiab qib siab PE rov ua dua tshiab ntxiv rau cov hmoov ntoo, calcium hmoov thiab cov khoom siv me me.PVC ntoo yas yog tsuas yog ua los ntawm PVC resin hmoov, PVC siv cov ntaub ntawv, ntoo hmoov, pob zeb hmoov thiab qee qhov kev hloov kho.

③ Cov khoom sib txawv: PE ntoo yas khoom hnyav, nrog siab hardness, brittleness thiab creep.PVC ntoo yas khoom yog lub teeb nyob rau hauv qhov hnyav, tsis zoo nyob rau hauv hardness, zoo nyob rau hauv toughness thiab creep.Lawv tsis loj npaum li PE cov khoom yas yas.

④ Kev siv sib txawv: PE ntoo yas cov khoom lag luam feem ntau tsom rau kev tsim vaj tsev sab nraum zoov, xws li guardrails, pem teb, cov thoob khib nyiab, paj txaj, tais, thiab lwm yam. PVC ntoo yas khoom yog cov khoom siv kho kom zoo nkauj rau sab hauv tsev, xws li lub qhov rooj, pem teb, skirting. kab, qhov rooj jambs, thiab lwm yam.

Kuj tseem muaj kev faib tawm zoo dua ntawm cov ntaub ntawv yas ntoo - ABS ntoo yas.ABS ntoo yas khoom yog ib qho yooj yim rau txheej txheem, muaj lub zog zoo, thiab tseem tuaj yeem siv rau cov nyhuv ntoo, uas zoo nkauj thiab tsis yooj yim rau kev puas tsuaj.